Dustin W.

Works great on my K390 .

Luis M.

Great stone really like how it sharpens my knives

Jack O.

Im going against the grain here.. I just received the Venev Cerberus Dog dual sided 100/240 and the 400/800 a couple days ago. Both are.. very disappointing. I got this for the worksharp precision adjust series. Yes, I have an aftermarket stone holder and yes, I know how to compensate for the different height vs angle. And no, sharpening with different types of guided sharpeners is not new to me. Also, yes, I read the care guide prior to use..

Long story short they take off almost no steel, or at least in a way I'm not used to and what they do is odd. It's like it's burnished by the stones. I am accustomed to hitting the apex, forming a burr, and removing the burr, etc for regular sharpening. The burr is something you can feel and also see. The 100/ 240 does not produce this. At all. Instead, it leaves strands of metals sticking out from what should be the apex. No burr forms, and yes, I use the sharpie trick and hit the apex, remove bur and continue with stone progression. Like i would with diamond plates or regular stones. Nada. Zip. Nothing. I have also tried using this freehand. It messed up my already set edges that I thought I would see how they performed on and to improve them, and these venev left them with, well, nothing just a ruined/ dulled apex and nothing else to show. Trying different angles, techniques, etc did nothing. In other words it didn't sharpen to a lower grit edge or remove steel. And no burr.. I have not encountered whatever results these stones produce except from already worn and dished out plates. Steels used were CPK Magnacut, INFI, Spyderco s30v, and CPM 3V

So I tried the 400/ 800 that I bought with the above stone. Got similar results, none or dulled or just damaged, with the added discovery that the stones were wavy and not at all remotely flat.

I openly acknowledge operator error is a possibility but based on my previous experiences with other plates and sharpeners, I am not confident the error is exclusively mine. Anyway, I regret buying these. The two I got were definitely dumpster worthy. Will not buy more from this company

john g.

Item is as described. You can tell everything it of high quality…stones, strops, stone holder, etc. All huge upgrades to a very affordable system. Mirror edge/hair popping sharp.

Benjaman M.

Fast shipment grate product have been using you guys stuff for a long time now couldn't imagine shaping with out the stones keep up the good work and aw products

Elizabeth M.

The items I ordered are for a Christmas gift. The order was placed and received in a very timely manner. I was very pleased with the purchase.

Mark F.

Everything I ordered has been great! Really makes sharpening easy to get a really sharp edge fast and consistent!

Daniel D.

Works great.

Best stones out there for the money, and then some.

Daniel O.

I used these stones with the 4" stone holder on my work sharp. This is my first experience with venev or any stones other than the work sharp stones. Was disappointed at first because the hight of the venev with 4" stone holder is different than the WS stones so I thought I was screwed, but I was able to raise the angle and still hit the entire edge and get a mirror polish with a screamin sharp edge. Wasn't the perfect scenario I imagined when I bought these but glad I was able make the proper adjustments and achieve an edge that just isn't possible with the WS stones. Glad I gave these a try.

Joe T.

The stones themselves are great, my order came in good shape. I live in canada, and the issue that I had was that when the package was delivered, I was hit with a $96 Duty charge from the cbsa. Very frustrating, as the tax was over 50% of the total cost of the items that I purchased! $55 of that charge was for my little angle finder that was in the package as it was an electronic item! The tax was over three times the cost of the object itself! Very frustrating. As a result, I unfortunately will not be buying any products in the future

Daniel A.

made some re-profiles a breeze. excellent stone!

Walt V.

This is a wonderful little stone that cuts very fast. It would be nice, however, if the grit progression was such that I didn’t have to change two stones back and forth to go from 80 to 100 to 150 to 240. As it is, the 80 and 150 are on one stone and the 100 and the 240 are on another. Therefore, to make the small jumps in grit progression, I must change stones to accomplish that. A nitpick, to be sure, but it’s worth considering the change.

Tim B.

Good stone, great service. Love gritomatic!

Ognian Ivanov

It is a great stone.Easy to work with. It was shipped quickly. 5 stars all the way.

David Hess

Very nice quality

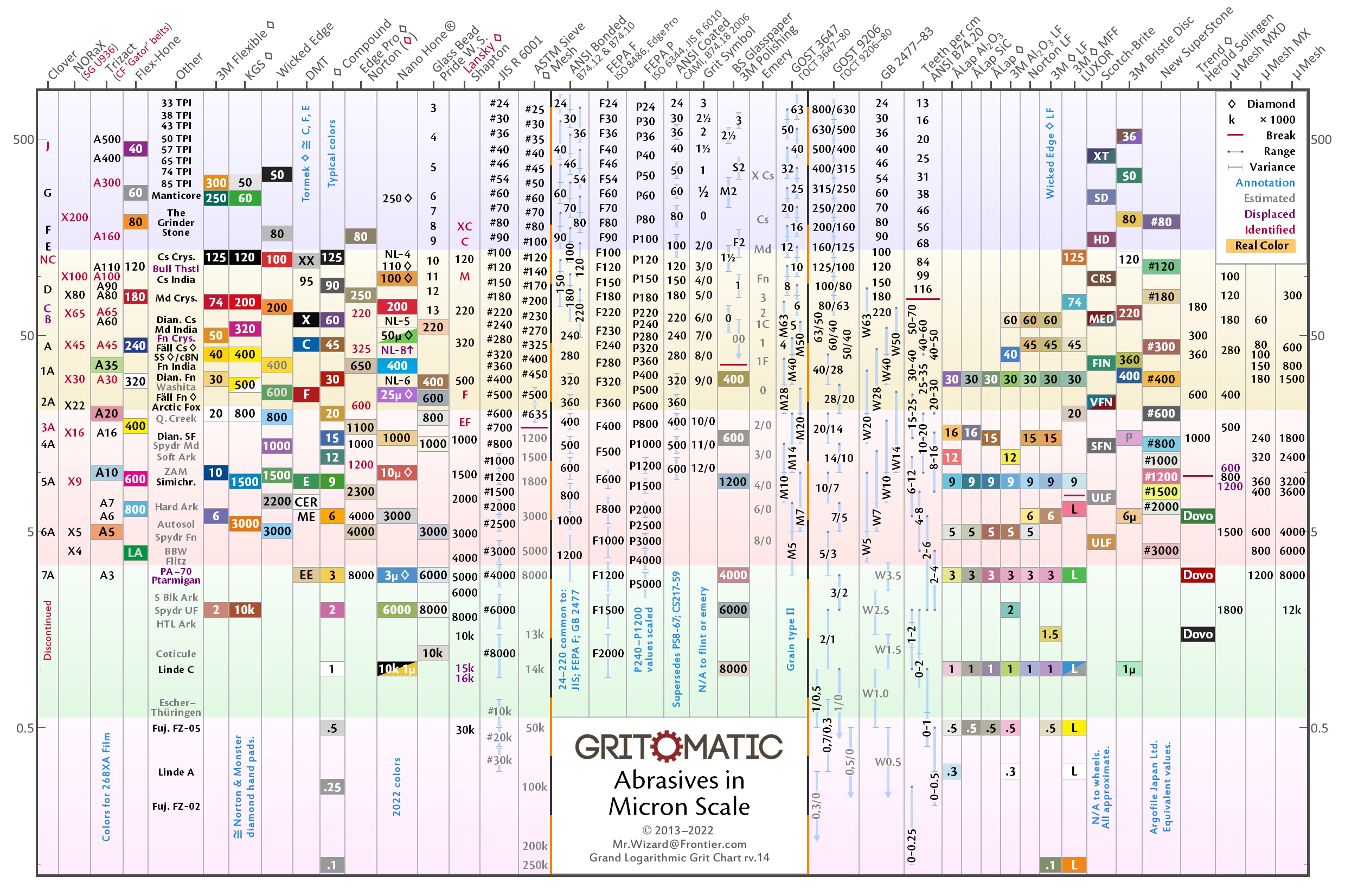

These are really nice stones and are so smooth with just a dab of water on them. The only complaint is that even the 100 (I know the F grout system isn’t the same as JIS and it’s actually closer to about a 200-250 grit) doesn’t remove much metal at all on harder steels when trying to reprofile an edge. I gave up on 15V and went back to my 220 grit plated diamond plate to hog off the edge and get it dropped to a 14° bevel. Bonded resin stones definitely don’t have the same bite as a plated stone. But they feel much better and leave much less aggressive scratches. Overall if I was working with a softer steel or not removing a bunch of metal I’d definitely take these all day long.

David Hess

Very nice quality stones

These things are amazing and soooooooo smooth feeling with just a splash of water. I used these to put a VERY shiny mirror polish on my edges. They clean up any of the feint scratches left after my 800Jis grit diamond pates and leave a very very smooth and shiny bevel. I just REALLY wish they’d get some of the middle grit stones back in stock so I could progress through the grits with ALL Venev stones. I’ve been checking for months and they’re STILL out of stock of so many of them.

Lee Simmons

1200 + 1500 dog series

Excellent for finishing a working edge, would definitely like to check others in series but they are not in stock. Would be great if they were easier to get

Stacy O’Day

Must have

If you are serious about putting the best edge possible on your blade using a Worksharp Precision Adjust then you need these stones!

I thought I was putting a good edge on my knives with the Worksharp stones but these take sharpening to a whole new level!

Stacy O’Day

Must have

If you are serious about putting the best edge possible on your blade using a Worksharp Precision Adjust then you need these stones!

I thought I was putting a good edge on my knives with the Worksharp stones but these take sharpening to a whole new level!

Scott Horn II

Excellent upgrade for my WSPA especially with the v block clamp stabilizer. The Russian girt numbers are indeed different than your typical Japanese grit equivalent, but I’d say the 1200+1500 equates to something more like 1600/2000 ish…. There’s a table on the site but it’s difficult to read.

Overall, I got the 100/240, 400/800, and 1200/1500 Cerberus Dog stones and if done correctly can get perfect mirror edges outta of the 1500 grit progression all day. Too bad the clamps weren’t in stock when I ordered, I could really use the 2 position forked clamp that’s a little longer than the WSPA. Great stones, awesome stone holder, the 5 dolla v block for the clamp is the most important thing keeping it as flex free as possible!! Highly recommend the 4” holder set up for the WSPA

Glenn Chappuis

Just perfect

Walt Voss

Dandy!

These two stones are great set ups for the higher grit stones and leave a nice edge that is perfectly fine if you prefer a little more bite in your finish.

Walt Voss

Nice polish

These narrow (but thick) stones leave a nice polish on my knives with harder steels (K390, ZDP189, S110V) with little effort. A light touch does it!

Daryle Trefz

Excellent quality

Love these stones! Great quality and wider and easier to use than the ones that came with the Work Sharp

Daryle Trefz

Get them while you still can

Love these stones! Great quality and wider and easier to use than the ones that came with the Work Sharp

Lee Cory Jr

I prefer the Venev stones over the diamond stones that came with my KME system. And by the time I'm at the Venev 1500 grit it's a nice mirror polish!

Robin Hette

As always, good stuff

Very good stone, never tried their 1500 or 2000 grits. It's seems that there are some stray particles causing some weird scratches, but it still works like a charm.

Anonymous

This is a Test. it is only a Test ;<)

Bought this to test before investing in a larger stone. Woah! Best cutting with feel I've ever experienced and have been making custom knives professionally for over 47 years.

Extremely smooth silky feel while sharpening. I've seen reviews where it was said that they feel similar to a ceramic stone. Uh-NO!!! Vastly superior and fantastic for higher carbide steels.

KnifeMaker

Michael L

Just rec'd the 400-800 version and fell in love with the smooth tactile feel while sharpening. Heard it felt similar to a ceramic stone in use. Well, no! Much better feel, far faster with better pattern on the edge. I've been a custom knife maker for over 47 years (now retired, and I can tell you, after purchasing this stone to test, it is the best stone I've ever used. and I've used a LOT of stones of many types. Now to pick up larger ones. LOL!, KnifeMaker

michael phillips

I have only sharpened one knife so far but work very good

michael phillips

worked very good

![Серия Venev Cerberus Dog с двусторонним бриллиантом [4 x 0,6 дюйма]](http://ru.gritomatic.com/cdn/shop/files/venev-cerberus-dog-series-dual-side-diamond_490x.progressive.jpg?v=1764726785)

![Venev Orion Series Diamond [6" x 1"]](http://ru.gritomatic.com/cdn/shop/files/venev-bonded-diamond-for-edge-pro_600x.progressive.jpg?v=1764726752)

![Venev Centaur Series Dual Side Diamond [6" x 1"]](http://ru.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond_600x.progressive.jpg?v=1764726757)

![Venev Gemini Series Gen.2 Curved Diamond [6" x ½"]](http://ru.gritomatic.com/cdn/shop/files/Gemini_20-_20Front_600x.progressive.jpg?v=1764726653)

![Venev Centaur Series Dual Side Diamond (3)Stone Set [6" x 1"]](http://ru.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond-full-set_600x.progressive.jpg?v=1764726778)